For “Sandwich Panels”,maybe you will consider how much do they cost,expensive or cheap,how to install it,and how to find and choose the cheapest one,how much do they cost, what is the best way to install them, and where are they the cheapest and etc...

Below short introductory guide of thermal insulation sandwich panels for you reference.

A sandwich panel is a product used to clad the walls and roofs of buildings. Each panel comprises a core of thermal insulating material, skinned on both sides with colored steel metal sheet.

Sandwich panels are not structural materials but curtain materials.The types of sandwich panel are generally grouped by the thermal insulating material used as the core.

Sandwich panels with cores of EPS, Rock wool ,Glass wool and polyurethane (PIR) are all readily available.

The materials mainly vary in their thermal insulating performance, sound insulating performance, reaction to fire and weight.

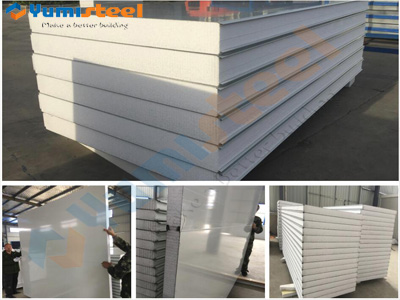

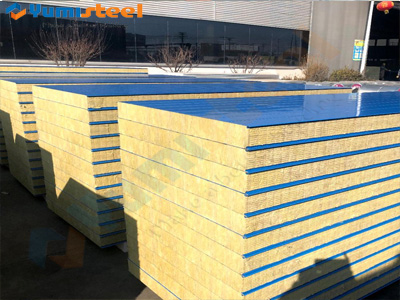

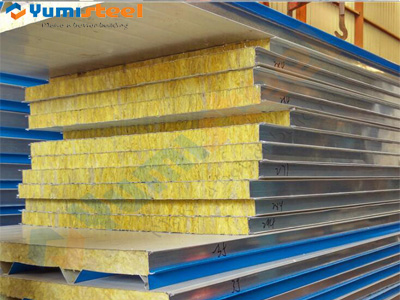

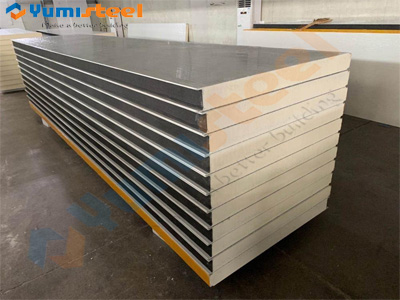

Below sandwich panels pictures with different core for reference:

|

This panel is cheaper and suitable for roofs of industrial buildings: production halls, storage buildings, commercial halls, farm facilities. |

|

Good function for Soundproof ;Waterproof and Heat preservation.... |

|

Glass wool sandwich panel: Glass wool as core material,it is fireproof can stand high temperature up to 1000℃. |

|

Its core made of stiff, freon-free, self-extinguishing PIR/PIR+ foam with very good thermal insulation properties. |

Sandwich panels are widely acclaimed due to a number of benefits, mainly those related to cost.

They’re suitable for insulating ceilings, interior and exterior walls (including partition walls and facades) and roofs-as well as for firewall applications.

Increased fire protection–stone wool core insulation integrates non-combustible properties to sandwich panels, delivering the highest fire classification A1.

Acoustic capabilities–blocking unwanted noise from attached or neighbouring buildings

Thermal performance–temperatures are better regulated in buildings, thanks to the smart fibre structure of stone wool insulation.

Construction time–A building based on a traditional masonry process may take 6 to 7 months to complete.A building of the same volume utilising stud partitions takes just 1 month to complete.The sooner a production building or warehouse is commissioned for use, the sooner a return on the investment can be achieved.

Stud partition buildings are assembled rather than “built”. The finished structural parts and cladding components arrive on site, and are then assembled like a house of toy bricks. Another plus is that there is no need to wait for the building shell to lose excess moisture.

Construction processes–Traditional masonry construction uses ‘wet processes’, which require significant amounts of water to make the mortar for bricklaying, concrete for casting or the plaster for rendering.

Stud partition construction is a ‘dry process’, with no water needed for the construction materials. A dry process requires only the assembly of the structure and fixing of the cladding (here, the sandwich panels) with screws.

How to install the wall or roof with sandwich panels?

Sandwich panels are easy and quick to install. From practical experience, installing 600 ㎡ of sandwich panels takes approximately 8 hours for a proficient construction crew.

Any type of sandwich panel will do as cladding for walls and roofs. Depending on the project needs, the wall or roof cladding may include:

①EPS-core sandwich panels (the budget option);

②Rock wool-core sandwich panels (for structures with improved resistance to fire);

③PIR-core sandwich panels (whenever good thermal insulation parameters are essential).

Sandwich panels can be utilised in all structure types. Your imagination is the limit.

However, while sandwich panels are generally used in industrial applications, some housing projects also use sandwich panels.

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964