What is EPS sandwich panel?

Expanded Polystyrene panels, also known as EPS panels, are a type of construction material made from expanded polystyrene foam. These panels are engineered by compressing and heating the foam, leading to the formation of rigid, lightweight sheets that show excellent heat transfer resistance and structural rigidity. However, singularly they cannot be used to create walls as they are soft and prone to damage on impact. They are used in combination with other material to create wall panels.

Sandwich EPS panels, also known as Structural Insulated Panels (SIPs), are composite building material consisting of three layers. The EPS panels forms the central layer also known as ‘core’, which is protected by outer layers of high strength material. Expanded Polystyrene (EPS) with flat or undulated surface profile in a single piece, is commonly used as core. The core is known for its excellent insulation properties. This core is sandwiched between two facing materials, like oriented strand board (OSB), plywood or any other sheet material creating a rigid and durable structure. The panels are designed to be exceptionally strong, durable, and versatile, making them a popular choice in modern construction material.

Types of EPS sandwich panels

EPS Sandwich panels are composite building materials. The EPS core is pivotal, offering excellent thermal insulation. Its lightweight, rigid, closed-cell foam structure maintains a pleasant indoor environment. With various types of EPS panels available, different building requirements can be fulfilled, each with unique properties for specific applications.

The facing material is crucial for the panel's structural integrity and provides a surface for finishes. Options for facing materials include aluminum, OSB, plywood, fiber concrete, MgO, or reinforced concrete. Choosing the right material is essential as OSB, plywood, and composite siding differ in fire resistance, moisture and mildew resistance, and toughness compared to metal or concrete panels.

EPS sandwich panels come in multiple thicknesses and can be customized. The thickness affects thermal insulation efficiency and load-bearing capacity, making it adaptable to specific project needs.

Production process of EPS sandwich panels

This vedio is the EPS production process for your reference.

Advantages of EPS sandwich panels

☆Excellent Thermal Insulation

EPS sandwich panels offer outstanding thermal insulation. Their EPS core with a closed - cell structure reduces heat transfer, keeping indoor spaces warm in winter and cool in summer. This leads to significant energy savings on heating and cooling.

☆Lightweight and Easy to Install

EPS sandwich panels are lightweight, which simplifies transportation and installation. Their modular design allows for quick assembly on construction sites, reducing labor costs and shortening the overall construction time.

☆High Structural Strength

Despite being lightweight, EPS sandwich panels have high structural strength. The combination of the EPS core and strong facing materials can withstand various loads, providing a stable and durable building structure.

☆Cost - Effective

EPS sandwich panels are cost - effective. Their relatively low material cost, along with savings on installation and energy bills, makes them an economical choice for many construction projects without sacrificing quality.

☆Versatile in Design

EPS sandwich panels are highly versatile in design. Available in different colors, textures, and thicknesses, they can meet diverse architectural requirements, whether for industrial buildings, warehouses, or residential homes.

Applications of EPS sandwich panels

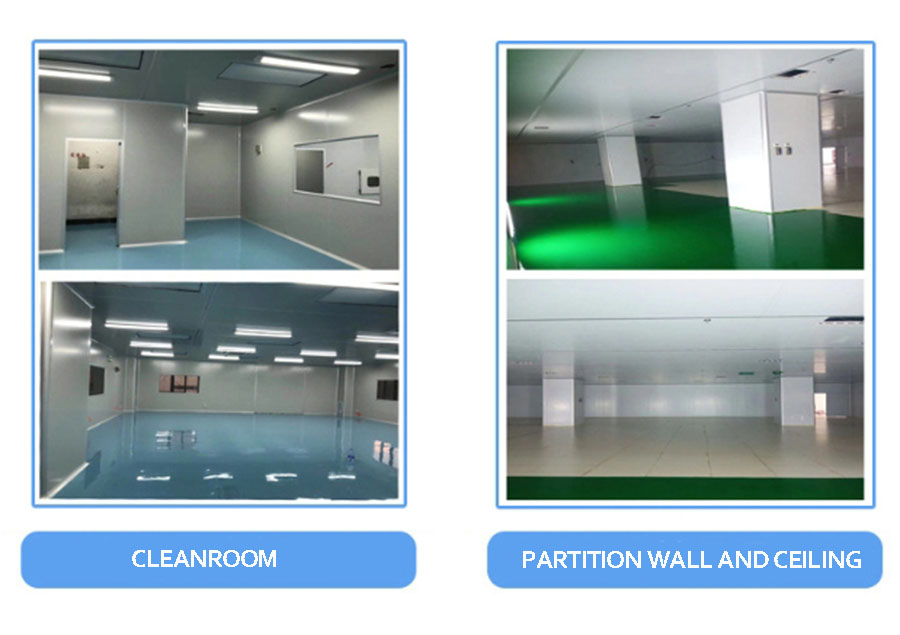

☆Cleanroom

In a cleanroom, EPS sandwich panels are ideal as they offer excellent insulation and are easy to clean, maintaining a sterile environment.

☆Partition wall and ceiling

For partition walls and ceilings, EPS sandwich panels' lightweight yet sturdy nature allows for quick installation and space division.

☆Medical institution

In a medical institution, EPS sandwich panels' fire - resistant and hygienic features ensure the safety and cleanliness of the facilities.

☆Laboratory

Laboratories benefit from EPS sandwich panels due to their noise - reducing properties and ability to provide a stable indoor climate.

Of course, EPS sandwich panels also have many applications in the field of construction.

In all,EPS sandwich panels have brought about a revolutionary change in the construction industry. Their excellent thermal insulation, lightweight structure, durability, and wide - ranging adaptability have transformed construction practices. For any construction project, be it a residential house, a commercial building, or a cold storage facility, EPS sandwich panels stand out as the optimal option for contemporary construction needs.

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964