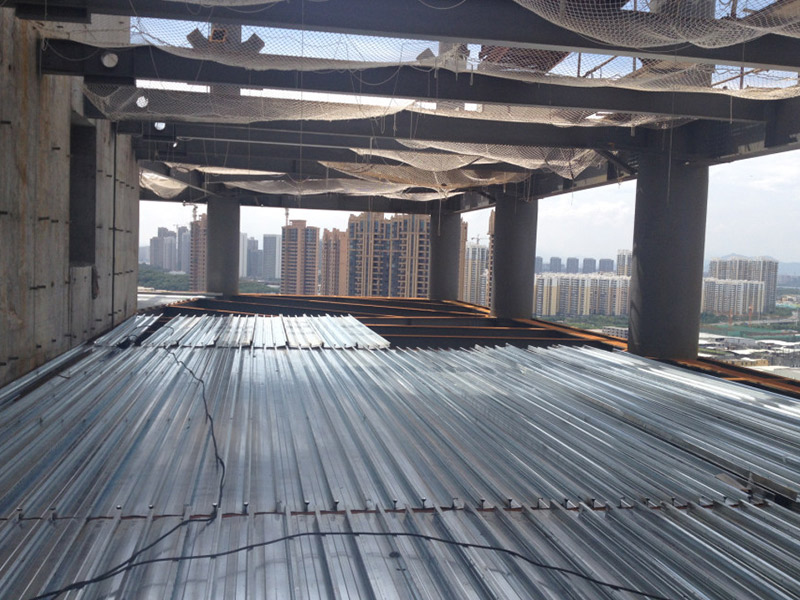

Profiled steel plates have been widely used in floor, roof and bridge decks in housing and industrial buildings. So in the face of many types of profiled steel plates, how should we choose?

Below I will briefly explain the selection comparison of open profiled steel plate and closed profiled steel plate and the selection comparison of closed profiled steel plate and steel truss.

Advantages of closed plate and open plate

1. The closed slab can be used as a composite floor, while the open slab can only be used under normal (non-fire) conditions:

2. The centroid of the closed plate is lower than that of the open plate, and the load is large;

3. The fireproof performance of the closed-mouth board is very good, and the high-rise and super-high-rise are used more, and our company has a fire protection report;

4. The floor slab of the closed slab is relatively thin, but it can meet the architectural requirements;

5. The slot of the closed plate can be used for hanging, etc.

At present, the fierce competition with the closed slab is the reinforced truss, which can meet the larger span, but the reinforced truss has the following disadvantages:

1. The transportation is troublesome, which may increase the cost;

2. The construction cost is high, which is 3 times more expensive than the closed plate;

3. Due to the damage caused by transportation problems, it is easy to produce slurry leakage;

4. It takes a long time to carry and borrow a crane;

5. Openings, pipelines are difficult to penetrate, difficult to handle, and prone to slurry leakage.

The third generation of profiled steel plate - steel truss floor deck

Reinforced truss floor slab is a kind of unsupported profiled composite floor slab; reinforced truss is shaped and processed in the backstage workshop. On-site construction needs to first fix the profiled slab on the steel beam with studs, and then place the reinforced truss. Binding is carried out, and concrete is poured after acceptance.

The steel bars on the deck and bottom chord of the steel truss floor are made of hot-rolled ribbed steel bars HRB400 or cold-rolled ribbed steel bars of grade CRB550; Commonly used is 0.5mm, and the amount of double-sided galvanizing is not less than 120g/m2.

As the third-generation steel floor slab, in addition to the advantages of the previous two generations of steel floor slabs and cast-in-place slabs, it also has advanced technology, fast construction, good seismic, fire-proof and anti-corrosion performance, stable quality, safety and reliability. The bottom of the board is flat, beautiful and environmentally friendly, the material selection is economical, the comprehensive cost is low, and the board shape is rich.

Application field

Reinforced truss floor slabs are widely used in different floor systems such as multi-high-rise steel structure floors, reinforced concrete structural floors, and reinforced concrete prefabricated floors. At the same time, it has also been widely used in different building applications such as irregular floor (circular, oval, other shapes) structural buildings, long-span structures, descending slab structures, thick slab structures, sloped roofs, and residential steel structures.

Advantage:

The mechanized production is realized, which is beneficial to the uniform spacing of the reinforcement bars and the uniform thickness of the concrete protective layer, which improves the construction quality of the floor slab. The prefabricated steel truss floor deck can significantly reduce the amount of on-site steel binding works, speed up the construction progress, increase the construction safety guarantee, and achieve civilized construction. The assembled formwork and connectors are easy to assemble and disassemble, can be reused many times, save steel, and meet the requirements of national energy conservation and environmental protection. The products independently developed by the steel structure are matched with automatic production equipment, which greatly improves labor productivity and effectively reduces product costs, and has compiled product production enterprise standards, design manuals, node structure atlas, and construction manuals. The product has been tested by the Civil Engineering Testing Center of Zhejiang University, and has undergone a number of engineering applications. Its performance can meet the requirements of the bearing capacity and deformation of the cast-in-place reinforced concrete floor.

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964