PIR LIGHT sandwich panel with rigid polyurethane core is coated in steel cladding. It guarantees thermal stability (aging lambda at 0.022 WmK) with thinner panels.

The Cold storage joint (labyrinth joint) used makes the panels maintain the highest tightness and continuity of thermal insulation.

|

Panel effective width: |

920~1120 mm |

|

Surface sheets: |

Steel sheets(0.40 ~ 0.70 mm); 304 Stainless stee(0.40~0.50mm); Al-Mg-Mn alloy metal sheets(0.60~0.90mm). |

|

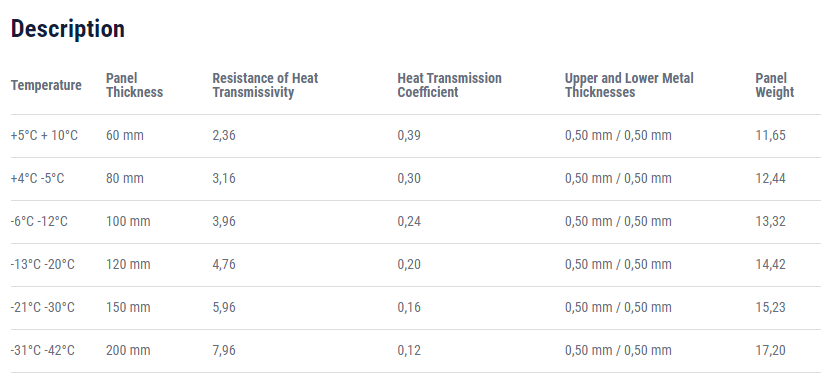

Panel thickness: |

30/35/40/50/75/100/150/200/250 mm |

|

Core material density: |

38 ~ 42 KG/M³ |

|

Regular color: |

White grey, Sea blue, White sliver grey |

|

Special color: |

As per RAL or customized |

|

Coating advice: |

PE, SMP, HDP,PVDF, etc. |

|

Length limitation: |

Max 5.9m for 20FT; |

|

|

Max 11.95m for 40FT. |

|

Main application: |

Cold room,food factory,cool room,freezer room,etc. |

|

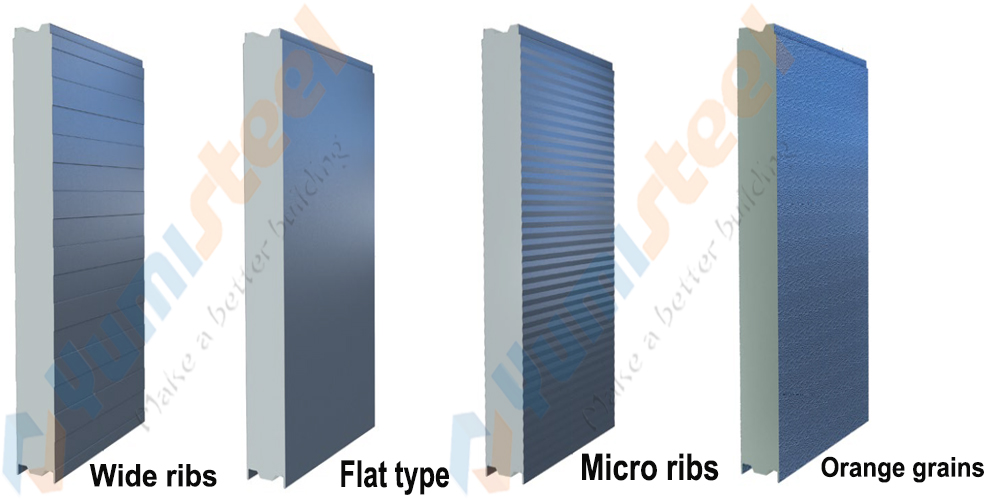

There are 4 types of panel surface profiled for your choices.Wide ribs,Flat type,Micro ribs,Orange grains.

Its huge advantage is lightness - comparable to boards with a polystyrene core. At the same time, PIR Light provides better thermal conductivity when using a thinner version of the panel (60 instead of 100 mm).

PIR LIGHT sandwich panels are characterized by stability of thermal parameters – with aging lambda at 0.022 WmK;

great resistance to soaking and capillary inactivity (no water rising);

lightness make the panels an excellent alternative to those with a polystyrene core;

the economical solution while maintaining the most important functions of a PIR sandwich panel;

highly resistant to mold and fungal infestation, and even nesting by vermin (insects, rodents, or birds).

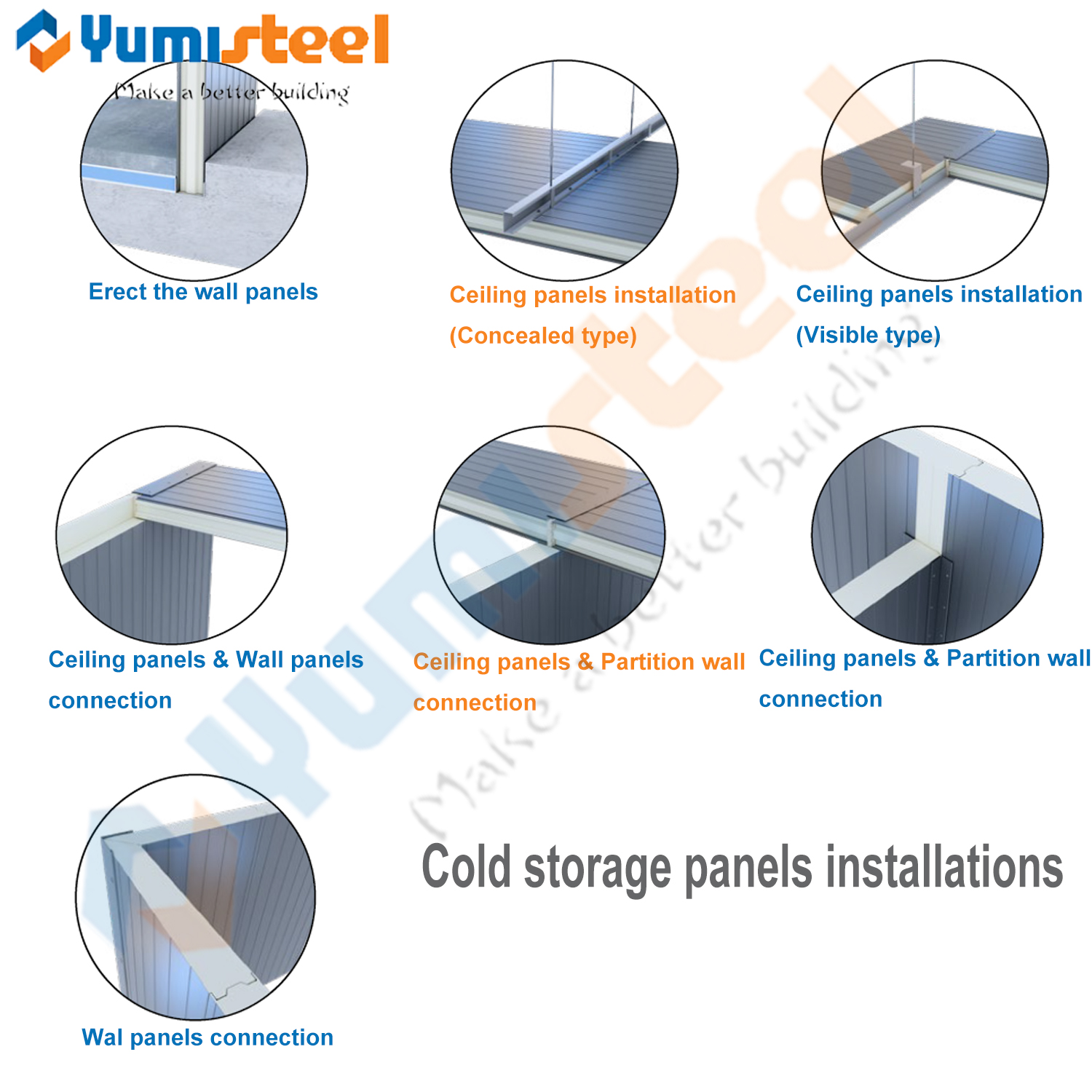

How to install the insulated sandwich panel?

For more details,please freely to contact us.

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964