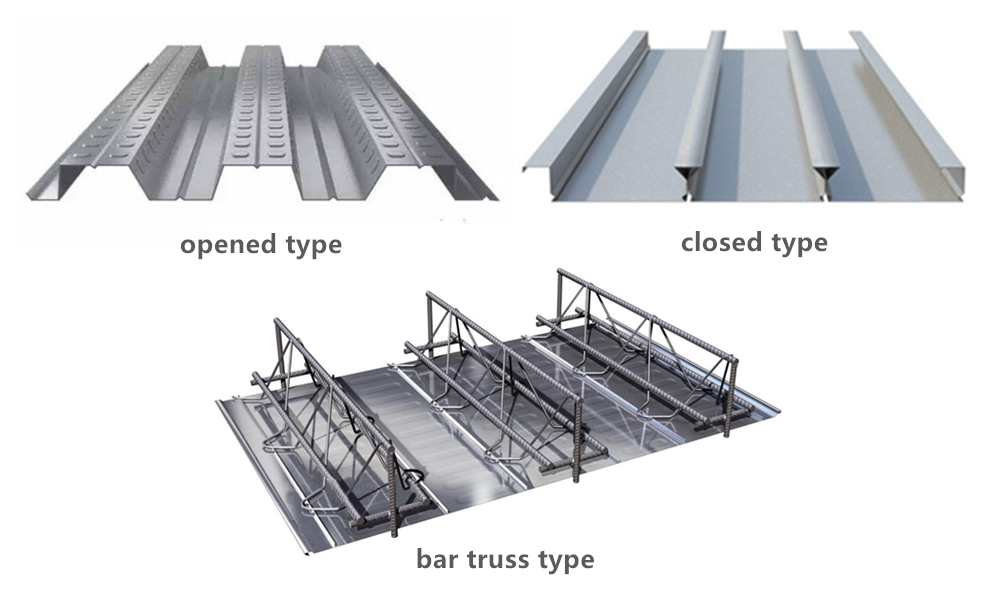

Currently, three types of floor support sheets are frequently used: opened type, closed type and bar truss type. Although their characteristics and advantages are different, installation method of each one is basically similar.

The construction process of the floor support sheet is generally like this: elastic wire → clearing board → lifting → arrange site → cutting → pressing → side welding → end welding → retaining hole → blocking → acceptance → bolt → bar arrangement → buried parts → Pouring beton→ Maintenance. Certainly, the finish of these complicated processes are inseparable from good labor organizations. The following processes can also be handled separately according to the actual situation on site.

Labor organizations can be divided into two groups:

The first group is responsible for transporting construction materials, including clearing and reversing, until the load bearing sheet are hoisted to the construction site according to the construction progress. This process requires five persons for lifting.

The second group is responsible for laying, including bar arrangement, cutting, installation, and hole retention. Every three people are a group, responsible for one section, and four groups work at the same floor at the same time. When tying reinforcement and pouring concrete in the next process, special personnel should be assigned to strengthen the maintenance of the paved deck sheet.

The specific method:

1 - The center line of the steel beam is popped up in the paving area. The center line of the main beam is the control line for laying the fixed position of the load bearing sheet. The center line of the main beam controls the overlap width of the overlapped girder of the floor bearing sheet, and the center line also determines the location of welding point where between the floor bearing sheet and the penetration welding of the girder. The center line of the secondary girder will determine the welding position of the penetration weld pegs. Because it is difficult to observe the specific position of the secondary beam flange after the floor bearing slab is laid, the center line of the secondary beam and the width of the secondary beam flange are rebounded on the center line of the main beam. Then rebounding back to the floor bearing sheet on the secondary beam when fasten the pegs.

2 - At the material stacking site, the floor slabs should be layered and partitioned according to the list of materials, and numbered. Distinguish the material situation in each layer, area, and number, and accurately transport them to the designated position.

3 - A special soft sling is used during lifting to ensure that the floor support sheet is not deformed as a whole and partially curled. Multi-layer designed steel structure generally adopts the installation process of three-layer for one-column. When installing the floor bearing sheet, the construction should be synchronized with the steel structure column beam, and at the least three floors between them. Therefore, when hoisting floor decking sheet, they can only pass through the upper beams and columns, and the crane should be layered and controlled between the beams and columns.

4 - Using plasma cutting machine or plate nipper to cut off the corners, and the surplus should be controlled within 5mm when cutting and paying off, and measures should be taken when pouring concrete to prevent slurry leakage.

5 - The connection between the load bearing sheet and the side is clamped by biting pliers, so that the single piece of the load bearing sheet is connected into a whole board. Firstly, weld the side of the sheet and then fix the two ends, finally fix it with pegs.

6 - At the end, the concrete must be maintenance for the whole effect.

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964