In the process of new bridge construction, a critical decision is whether to use prefabricated bridges or traditional on-site construction methods. This choice directly impacts the project timeline, cost, and overall quality, making it essential to conduct a comprehensive evaluation based on engineering conditions and objectives.

What are prefabricated bridges?

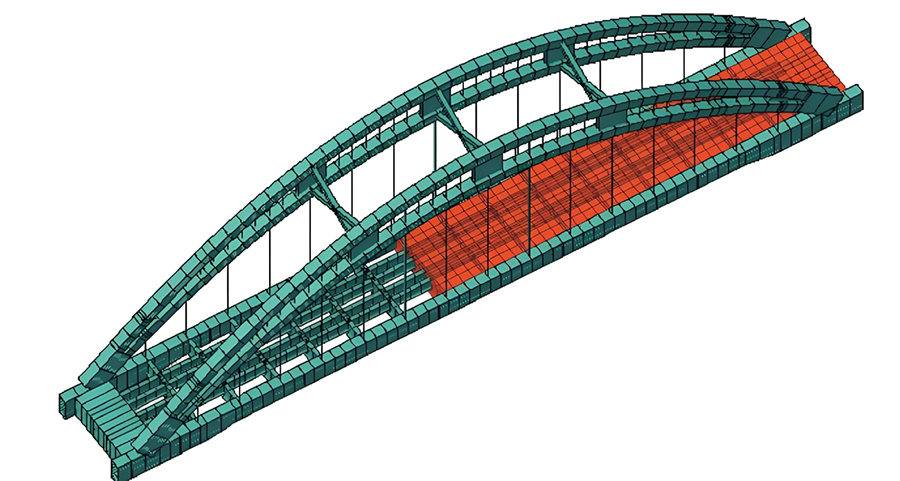

Prefabricated bridges refer to a construction method where bridge components are manufactured in a factory in advance and then transported to the site for assembly. Its core principle lies in transferring the production of main structures to a controlled environment, minimizing on-site wet work and weather-related disruptions.

Advantages of the prefabricated bridges

☆Accelerated On-Site Construction

Prefabricated bridge systems drastically reduce on-site assembly time. This minimizes traffic disruptions, lowers labor costs, and shortens overall project schedules, enabling faster completion.

☆Superior Quality Control

Factory-manufactured components ensure consistent precision and high-quality materials. This results in enhanced structural durability, reliability, and long-term performance.

☆Eco-Friendly & Sustainable

The controlled production process reduces waste and allows efficient material recycling. This method supports sustainable construction with a smaller environmental footprint.

☆Long-Term Cost Efficiency

Prefabrication offers significant savings through bulk production, reduced weather delays, and lower onsite labor requirements. It delivers greater economic value over the structure’s lifecycle.

In summary, prefabricated bridges are particularly suitable for projects with tight schedules, complex site conditions, or high requirements for quality control. As modern bridge construction advances, the rational adoption of prefabrication technology will play an increasingly important role in improving engineering efficiency and promoting sustainable development.

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964