Building houses using sandwich panels is becoming increasingly popular, thanks to their excellent thermal insulation, quick installation process, and outstanding structural durability. If you are also considering using this modern building material, this article will provide a detailed step-by-step guide on how to construct an efficient, sturdy, and aesthetically pleasing house with sandwich panels.

What are Sandwich Panels?

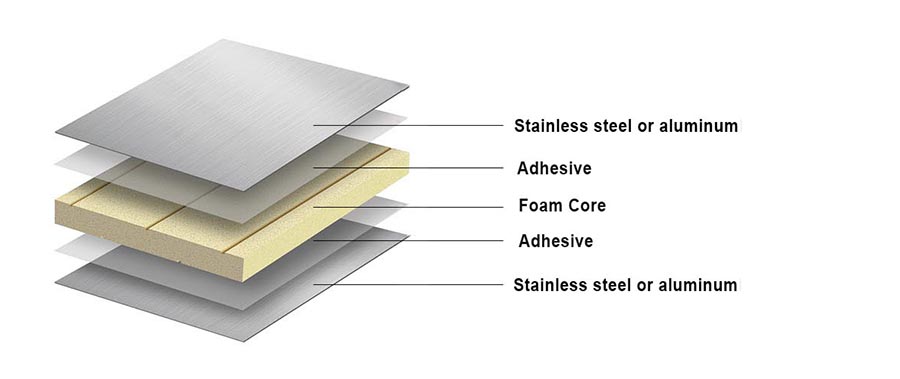

To understand the application of sandwich panels, one must start with their core structure. A sandwich panel is a composite building material, typically consisting of two robust outer metal facings (such as galvanized steel or aluminum) and a lightweight insulating core material (such as polyurethane foam, rock wool, or PIR), all bonded together by high-strength adhesive. This "sandwich" structure integrates load-bearing, insulation, and decorative functions, making it a highly efficient and versatile panel.

How to build the house?

Step 1: Design Planning and Customized Production

This stage involves completing the detailed design of the house, clarifying the layout, dimensions, and functions, and ensuring compliance with local building codes. Based on the final design drawings, customized sandwich panels of the required specifications are ordered from the supplier, including determining the panel thickness, finish, and insulation core material.

Step 2: Material Transportation and On-site Preparation

Once the customized panels are manufactured, their lightweight nature facilitates easy transportation, allowing for efficient delivery to the construction site. The site must have the foundation work completed and leveled in advance, while the delivered panels should be stored properly in preparation for installation.

Step 3: Installation and System Integration

Installation begins with the foundation, where specialized bolts or screws are used to securely fasten the panels to the structure. The panels are tightly joined together using specially designed connectors. Subsequently, according to the design, openings for doors and windows are cut into the panels, and channels or cavities are pre-embedded within the wall structure to integrate electrical, plumbing, and other systems.

What are the advantages of sandwich panels?

☆Excellent Thermal Insulation

Effectively reduces heating and cooling energy consumption in buildings, significantly lowering long-term energy costs.

☆Superior Fire Resistance

The core material typically exhibits excellent flame retardancy, effectively delaying the spread of fire and enhancing building safety.

☆Outstanding Structural Durability

The robust composite structure resists wind and rain erosion, ensuring building stability even in harsh weather conditions.

☆Strong Moisture and Pest Resistance

The dense panel and core material effectively block moisture penetration and prevent insect or pest infestation.

☆Good Sound Insulation

The "sandwich" structure effectively absorbs and blocks noise, creating a quiet and comfortable indoor environment.

In summary, using sandwich panels to build a house is a modern choice that balances efficiency and cost-effectiveness. The entire process begins with meticulous design planning, which must comprehensively consider the house's functions, dimensional layout, and compliance with local building codes. Subsequently, the custom-produced panels can be easily transported to the site for rapid installation. Ultimately, the structure gains multiple advantages, including excellent thermal insulation, long-lasting durability, and superior resistance to moisture and fire.

For more information needed or any inquiry,please feel free to contact Yumisteel team.

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964