The energy-saving design of cold storage room can be roughly divided into architectural design and system design. To explain it simply, architectural design is mainly relying on the design of the building from the overall to the individual to the specific components,in order to ensure and maintain the use conditions in the building. It is aiming at minimize the installed power of energy equipment and reduce the load on the room. Energy-saving creates conditions. Regarding system design, such as the design of refrigeration and air-conditioning systems, electrical systems, etc.. It mainly relies on the high efficiency of equipment and the system itself to achieve energy saving, when it’s meet up the power load. Architectural design and system design are complementary and must be combined organically to form a complete energy-saving design for cold room.

What should designers and specifiers need to consider, when looking to reduce energy usage in refrigerated room? Hereby we will have some recommendation for you.

☆ Building energy efficiency design

· Plan the general layout of the factory reasonably

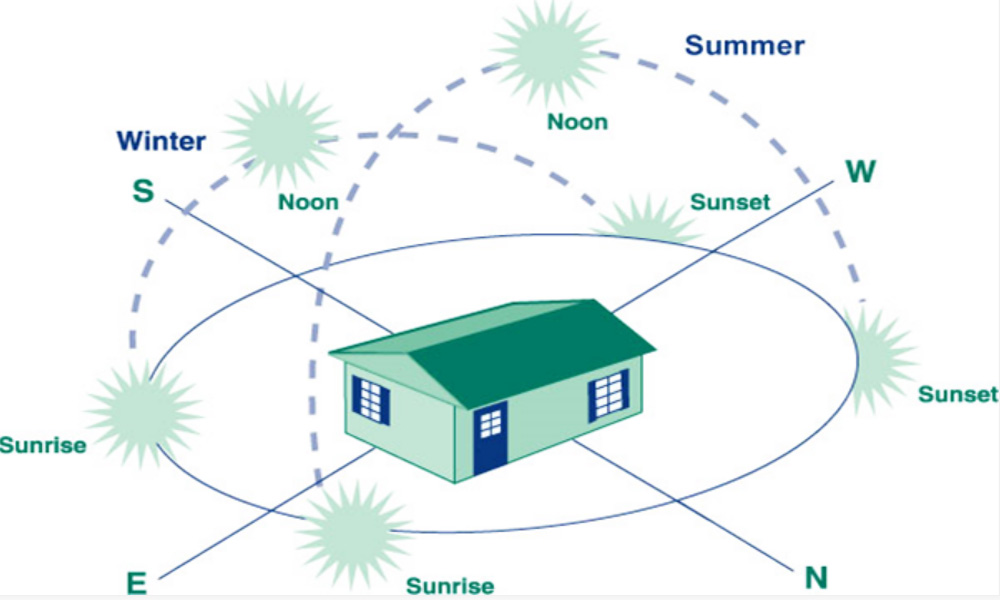

After testing, for buildings of the same shape, the cooling load of the north-south orientation is 50%-70% smaller than that of the east-west orientation. Therefore, choosing a reasonable building orientation is an important energy saving measure for cold storage room.

· Selection of insulation materials

Selection of Roof & Wall

To reduce the unit heat flow of the enclosure structure of cold room, one is to choose insulation materials with low thermal conductivity, and the other is to increase the thickness of the insulation layer. But the thickness should not be too thick, otherwise it will increase the construction cost and reduce the use of space and other issues. Therefore, insulation materials should be selected within a suitable thickness range. Thermal insulation materials for cold storage, currently mainly EPS, XPS and PUR/PIR are widely used.

|

For roof, the most important thing is to avoid water and vapor leaks.There are three important points we would like to suggest, when designing a successful roof system: - Keeping roof structural integrity at all times. - Sealing all joints positions,in order to prevent air and moisture infiltration. - Requiring uninterrupted vapor retarder. |

|

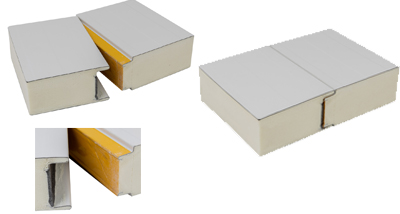

The current trend in the cold storage industry is to use preformed materials, for example, prefabricated insulated PUR/PIR metal panels and insulated concrete. - External wall, except to consider the wind, rain and snow load, you also need to consider vapor and heat transfer control. Well designed external wall will improve the entire heating and cooling load of refrigerated room highly. - Internal wall, according to different cold storage spaces temperature and layout requirement, then different design specifications must be considered. Except this, the internal walls of refrigerated rooms must also obey to food safety regulation. |

Selection of doors

Three main factors to choose the cold room door:

How the door will be used?

How often it will be used?

If the space required to pass a forklift or other equipment, its load, and the mast to pass through without hitting the door?

Except these, Door Activation methods and Life cycle costs are also need to be considered.

☆ Selection of cold storage equipment

· Compressors

For a refrigeration system, to choose a screw compressor, a piston compressor or a small compressor unit must be determined by comprehensive analysis and comparison, according to the scale of the cold storage and the processing and usage conditions. When designing, designers must master advanced technology and understand the characteristics and scope of application of various products. Generally speaking, the COP of the screw compressor is higher than that of the piston compressor, which is especially suitable for use in low temperature conditions with little change in load; while the small compressor unit is more convenient to operate and use more energy-saving in high temperature or air conditioning storage.

· Condenser

Evaporative condenser is preferred. Choosing an evaporative condenser not only saves the cost of water pumps, cooling towers and pools, but also has a water flow rate of only 10% of water cooling, which saves energy and electricity. The evaporative condenser should be arranged in a well-ventilated place as far as possible to avoid direct sunlight.

· Evaporator

For cooling equipment, try to use air coolers instead of top row pipes. The use of top row pipes is not only consumables, but also poor cooling efficiency. The evaporator should try to use hot gas to defrost or realize automatic defrost to reduce power consumption.

☆ Cold storage room solution

Yumisteel can offer solutions, especially for insulated metal cold storage roof and wall panel systems. Our diverse products will supply you one stop service.

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964