Insulated metal panels (IMPs) have been an integral part of commercial, industrial, residential construction projects for many years. Some people called it sandwich panels, laminated panels,etc. We believe that if you are involved in the construction industry, you should know this kind of building material.

But even professional installation team of steel buildings, they may do something wrong, and cause some installation mistake of insulated panels. Let’s make it simple for understanding for this sentence. If you own a newest super sport car, but you just regard it as a common car, do you think you have let the sport car play its role and you enjoy its function?

The installation mistakes we are going to talk about are minor errors, but they may cause costly and dangerous issues (total structural or thermal failure). Hope our suggestions below can help something about this, at least to reduce the time and money of house owner.

☆ Panel storage

There are some common mistakes that usually made at site installation. Here we listed as follows:

· Leave the panels under sunlight, without any cover or protection;

- All our laminated panels are with protective films, if under sunlight too long time, it will make it harder to peel the film. Also if you put panel outside and don’t put any waterproof cover on the panels, it will do harm to the panels, when there is a lot of rain. Especially the rockwool sandwich panels, it can't be place outside or any wet area.

· Place panels stack at somewhere no flat;

- Panels will be bent by its own weight, so please make sure panels are stack at a flat area.

· Too many packets of metal sandwich panels on each other;

- As per mentioned above, panels will be bent by its own weight,max 2 packets are allowed to stack together.

· Directly put the insulated metal panels on the floor;

- Without any soft sticks or sleepers under the panels, if there is any water or water vapor, they will damage the panels.

☆ During installation process

|

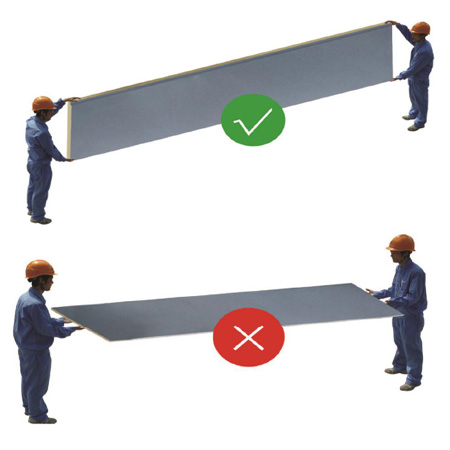

· Carrying the panel in wrong way. If the insulated panels are not carried in a correct way, it will make the panels bent and difficult to install in a vertical horizontal line; |

|

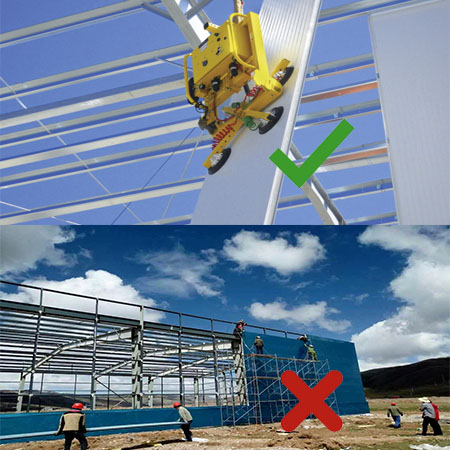

· Please use slinging gear suitable and compliant with the required safety measures, if the insulated metal panels cannot be mounted manually. Ensure that the sheet steel surfaces are protected; |

|

· No installing the metal sandwich panels with a level surface from the very beginning. Before laying the first panel, it is very important to make sure the panel is stay in same line as the steel structure. If failing to do so, can result in a poorly finished product. How to avoid? Installers need to check to make sure the purlins are level and square. This can be done by pulling a dry line across the steel or using a laser level. Most IMP manufacturers will specify the amount of tolerances they allow; |

|

· Poor Caulking and Taping. All the wall or roof insulated panels' installations involve the use of butyl caulk and butyl tape. Neither is difficult to apply, so mistakes are typically due to sloppy workmanship—the results of which may not be noticed until the rainy season or when cold weather and warm interior temperatures meet, causing condensation; |

|

· Lap joints are also very important, it's where two panels butt together. If failing to make sure the joint is tight, it will produce a vapor leak, compromising the integrity of the envelope. One reason would be a lack of experience on the part of the installer. Another reason is poor workmanship. Installation problems should be avoided at all costs when using IMP roofs because removing panels after the work has been completed to fix problems is very difficult, costly and time consuming. |

☆ Ending

To have a conclusion here, some advice for construction crews who are installing insulated panels.

· To know and understand the site conditions for the project. Is it ready to receive materials? Any conditions that might prevent the delivery of the product?

· Keep installation workers properly trained before proceed installation. This should be based on site situation, because what may have worked on a previous job may not be applicable to the new job at new site.

· To review and consult installation guides and construction drawings, when having doubt.

· To consult with the manufacturer before beginning the installation process, this is to avoid wrong installation process.

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964