A purlin is a critical horizontal structural component designed to provide intermediate support for roof systems. These load-bearing members typically span between primary framing elements (such as walls or rafters) to:

☆Distribute roof loads

☆Prevent rafter deflection

☆Create stable mounting surfaces for cladding

Common materials include:

☆Steel (Z/C purlins for metal buildings)

☆Timber (traditional wood-frame structures)

☆ Composite (engineered hybrid systems)

Modern applications range from industrial warehouses to residential roof reinforcement, where purlins enhance structural integrity while optimizing material usage.

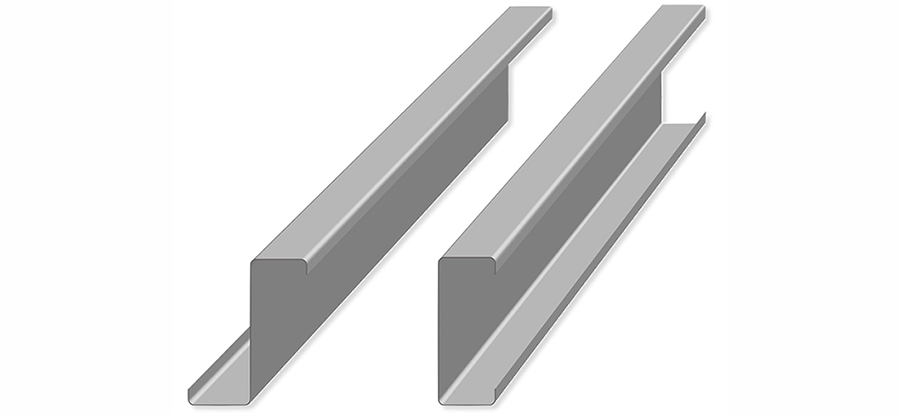

Currently, purlin manufacturers typically produce two main types of purlins – Z purlins and C purlins.

Let's first examine their specific characteristics.

|

C Purlin |

Z Purlin |

|

C purlins are shaped like the C alphabet and are primarily used to support walls and floors. Their smooth inner surface ensures seamless cladding attachment, while their structural simplicity makes them ideal for basic span constructions. These purlins are also perfect for simple span construction. |

Z purlins is a distinctive Z-shaped profile, formed from cold-rolled steel sheets for maximum efficiency. Compared to traditional hot-rolled angles, they reduce material usage by 50% while maintaining superior strength-to-weight ratios, making them ideal for cost-effective structural framing. |

What is the differences between C and Z Purlins?

|

Usage |

C purlins are used to form wall and floor joists in building shell structures. Z purlins are employed for roof and wall joists in building envelope construction. |

|

Angles |

C purlins feature a standard 90-degree angle, while Z purlins are designed with acute angles (typically 60-85 degrees). This angular distinction makes Z purlins more adaptable and flexibility than C purlins. |

|

Overlapping |

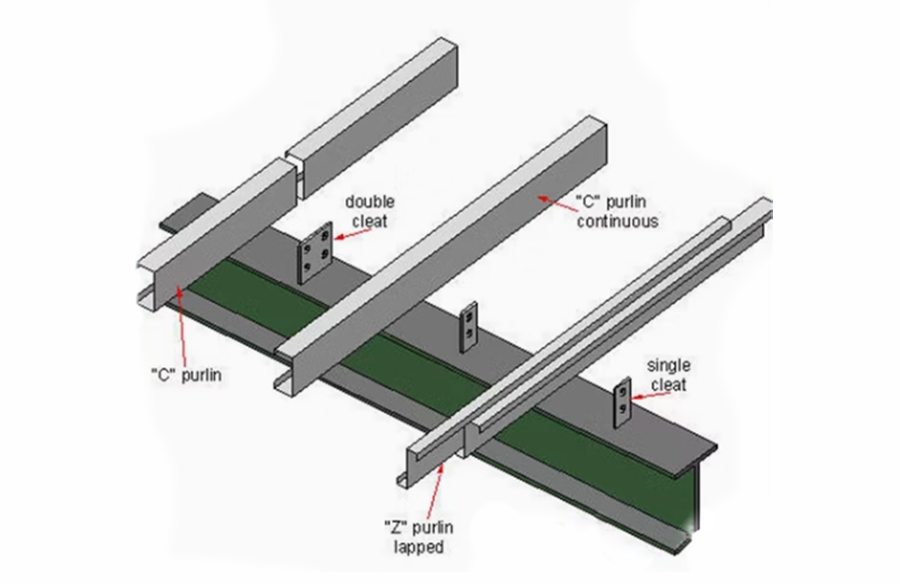

Z-purlins can be continuously lapped, whereas C-purlins cannot. Therefore, Z-section purlins are the preferred choice for metal buildings with larger spans. |

|

Roof Sloping |

For roofs with minor slopes, Z-section purlins exhibit a slightly greater difference in bending modulus compared to C-section purlins. However, as the roof pitch increases, the bending section modulus of Z-purlins symmetrically enhances along the slope direction. Consequently, Z-section purlins are more suitable for steeply pitched roofs. |

|

Support |

Z-section purlins are typically installed between roof panels to provide structural support, whereas C-section purlins are used as secondary beams for floor slab reinforcement. |

|

Strength |

Z-section purlins demonstrate superior load-bearing capacity, making them ideal for supporting heavy-duty structures, while C-section purlins offer relatively lower strength. Consequently, Z-purlins are the preferred solution for roofing systems and buildings requiring greater load capacity. These structural components are commonly implemented in agricultural and industrial construction projects. |

|

Installation |

C-section purlins offer simpler installation, while Z-section purlins require greater effort and technical expertise. This makes C-purlins an excellent choice for single-span steel frame roof structures. |

In summary,C purlins offer easier installation and cost efficiency for simple structures, while Z purlins provide superior strength and load capacity, ideal for large-span roofs. Their overlapping capability makes Z sections better for sloped designs. Choose C purlins for basic framing and Z purlins for heavy-duty or complex architectural needs.

Beyond roof and wall support, steel purlins reinforce mezzanine floors, creating extra space cost-effectively. Paired with beams, they form a sturdy framework, transferring loads to primary beams,just like in roofing systems,ensuring safety without expensive construction.

If you have any questions,please contact the Yumisteel team for tailored solutions!Thank you!

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964