Cleanroom panels are specialized building materials used to create ultra-clean, controlled environments. They are essential in industries like pharmaceuticals, electronics, and healthcare where strict hygiene, temperature, and air purity standards must be maintained.

What is Cleanroom Panel?

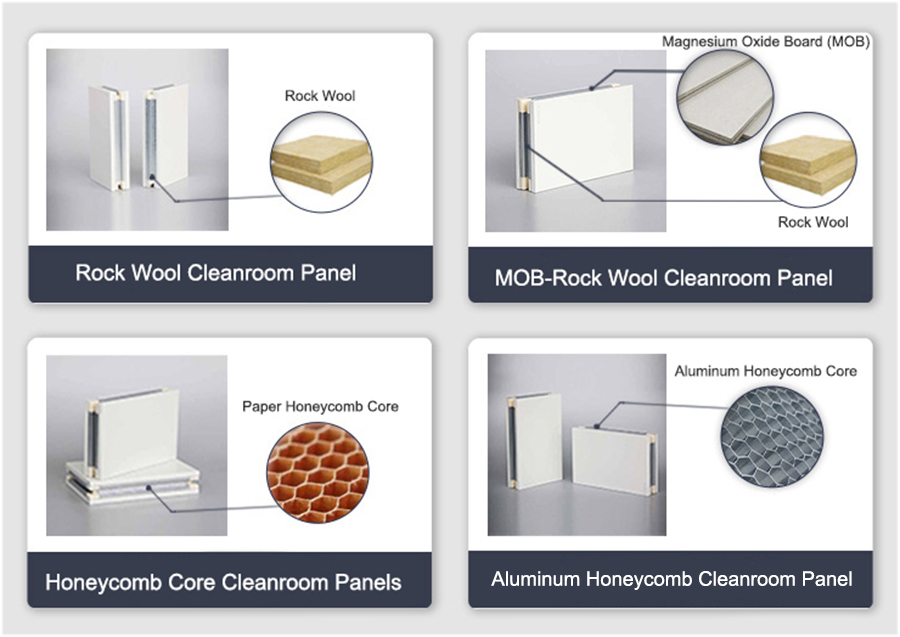

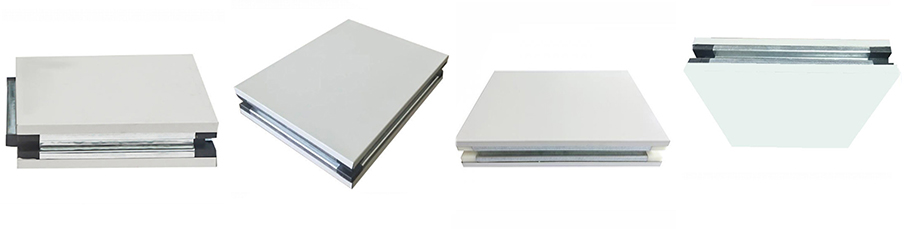

Cleanroom panel are handmade sandwich panel, with rock wool, hollow magnesium or rock wool and magnesium combined , paper or aluminum honeycomb as core material, prepainted steel sheet, stainless steel or high pressure laminate (HPL) plate as double-skin material, enclosed and strengthened by four profiled galvanized iron bars and four corner pieces. The aluminum honeycomb sandwich panel is characterized by its high pressure resistance ability, good tension, light weight compared with other panels.

What is the characteristics and functions of cleanroom panels?

☆Contamination Control

Cleanroom panels create a barrier that isolates the cleanroom environment from external contaminants, including dust, microbes, and other particles.

☆Material Selection

The materials used in cleanroom panels are chosen for their ability to withstand rigorous cleaning protocols, resist chemicals and moisture, and maintain a sterile environment.

☆Performance and Durability

Cleanroom panels are engineered to be durable, easy to clean, and resistant to scratches, impacts, and other damage that could compromise their integrity.

☆Modular Design

Cleanroom panels are often used in modular cleanroom systems, which allow for flexible and customizable configurations of the cleanroom space.

☆Integration

Cleanroom panels can be designed to integrate with various cleanroom components, such as air filtration systems, lighting, and other equipment.

What is the application of cleanroom panels?

Cleanroom panels are essential in various industries where contamination control is critical.

|

|

Pharmaceuticals:Ensuring the purity of drug products and preventing contamination during manufacturing.

|

|

|

Biotechnology:Maintaining sterile conditions for cell cultures and other sensitive biological processes. |

|

|

Electronics Manufacturing:Protecting delicate electronic components from dust and other contaminants during production. |

|

|

Medical Device Manufacturing:Ensuring the sterility of medical devices during assembly. |

|

|

Food Processing:Maintaining hygiene and preventing contamination of food products. |

|

|

Scientific Research:Providing controlled environments for research activities requiring high levels of cleanliness. |

In short, cleanroom panels are the essential building blocks for creating contamination-controlled environments. By providing seamless, airtight, and easy-to-clean surfaces, they are the fundamental reason industries like pharmaceuticals and microelectronics can operate reliably and meet strict quality standards.

If you have any questions,please contact the Yumisteel team for tailored solutions!Thank you!

years of experience

online service

online service +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964