Polyurethane sandwich panels are widely used in factories, warehouses, office buildings and other projects for the advantages of easy and fast installation, thermal insulation, fire protection, environmental protection, elegant appearance, and light unit weight.

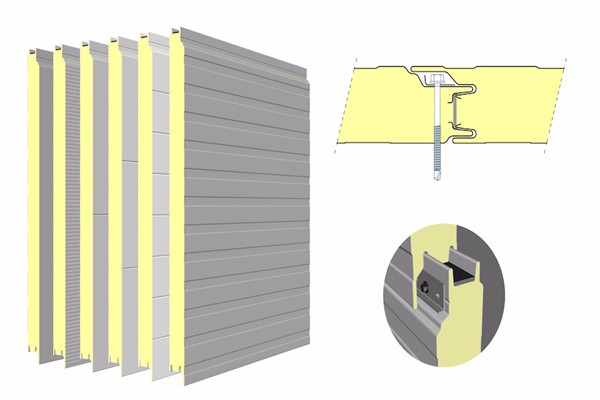

The panel is composed of inner and outer steel sheet and core material. The thickness of the outer steel sheet is generally 0.6mm, and the thickness of the inner steel sheet is generally 0.4mm or 0.5mm. The surface form of the outer steel sheet is normally divided into three types: flat, small corrugated and embossed and other 6 effects (preferably flat and small corrugated, many owners like to use pure flat); the core material is mainly chose rockwool, glasswool or Polyurethane material, which are mechanically compounded.

Installation process of PU metal sandwich panel

Material entry and unloading → Determining the elevation and axis of the starting board → Installation of the flashing board and pallet → Installation of the sandwich panel → Installation of the vertical metal inserts → Installation of the doors and windows edge→ Installation of the acorn nut of parapet and glue→ tear off the protective film.

Material entering and unloading

The on-site stacking site should be flat and hard, and the road can meet the transportation vehicles in and out. Every 10,000 square meters of metal sandwich panel needs about 1,000 square meters of stacking site. When hoisting, the panel parts in contact with the sling need to be protected with practical soft appliances. For sandwich panels with long lengths, three-point lifting should be used, and a flat pole should be used for the upper part.

When stacking PU sealing rockwool sandwich panel, in order to ensure foolproof, but also need to prepare enough plastic cloth to prevent rain, because the rockwool board that have not been installed will cause core damaged after long-term absorption of water.

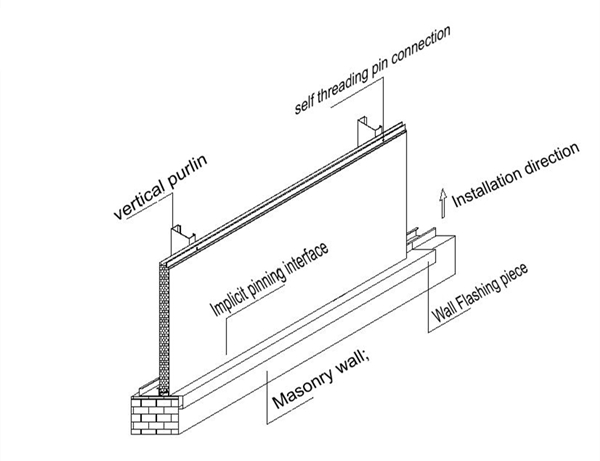

Confirmation of purlins

1. Confirm whether the purlin is installed in the same plane

2. Whether the verticality or displacement of the purlin on the axis deviates too much

3. According to the design, mark the elevation of the flashing board and the pallet, and the vertical ink line at the joint of the plate on the purlin.

The installation of flashing board and pallets

1. Installing the flashing board and pallet according to the line of elevation, as well as attentively using the lining board.

2. The installation of the inside and outside corners. Some companies use metal corner plates, which cut to be 45 degree angel on site.

3. Installing the inner longitudinal seam metal strip according to the ejected ink line, remember to stick the sealing tape and heat-preservation strip. Some projects do not need metal strips with inner longitudinal seams and replacing with plugging the insulation strips.

Some structure project uses the integration of flashing board and pallets, some pallets are steel plates.

The installation of PU sandwich panel

1. Lift the sandwich panel to the corresponding site according to the layout drawing, and using the special spreader for vertical transportation of the panel.

2. Installing the sandwich panel in order from bottom to top of the structure. The sandwich panel that needs to be cut should be cleaned of iron filings after cutting to prevent rust.

3. Using self-tapping screws to fix the polyurethane sandwich panel in the purlin. Pay attention to the nailing strength, and do not tighten the screws too tightly to prevent the deformation of the panel at the fixed place and damage the waterproof gasket of the screws themselves.

4. Attach waterproof seals and sealant on both ends of the polyurethane sandwich panel to prevent rainwater from flowing into the panel along the horizontal seam.

Finally, tear off the protective film packed into the mouth before installing the sandwich panel, otherwise it will be difficult to remove in the future.

years of experience